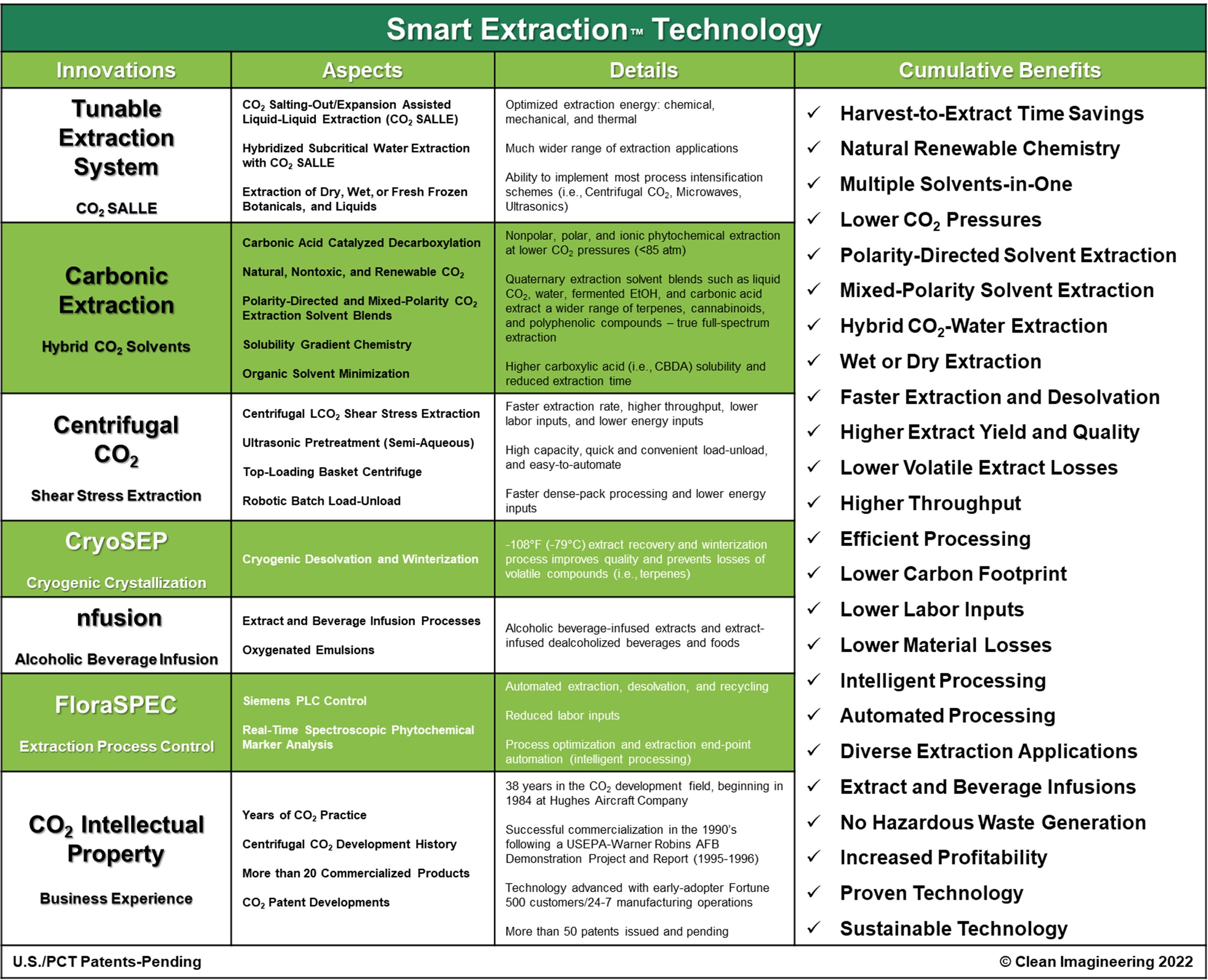

Tunable Extraction System

Collaborative Extraction

A Fully Integrated Extraction and Extract Treatment Process

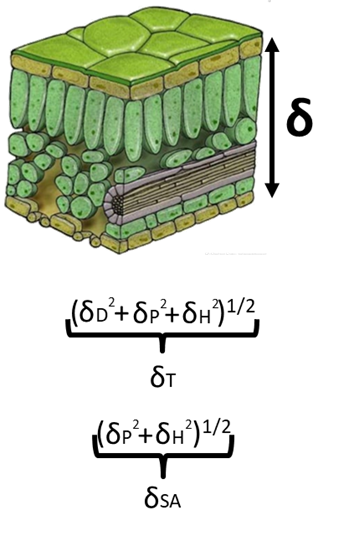

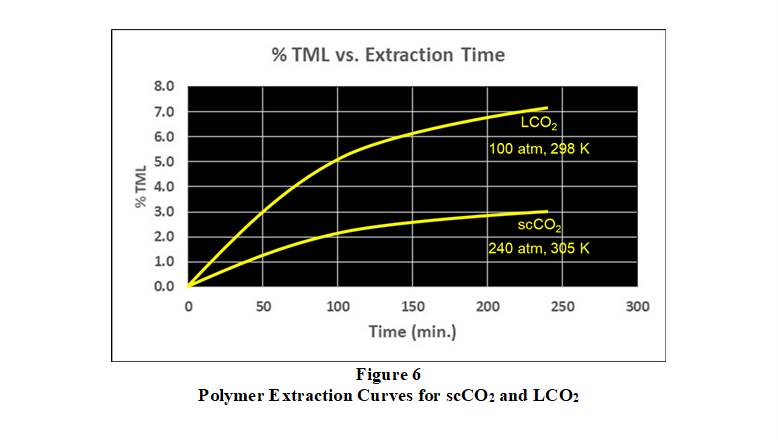

Novel polarity-directed and mixed-polarity CO2 extraction solvent systems and processes utilizing combinations of dense phase CO2, water, natural and eco-safe (and minimized) organic compounds and inorganic additives, solid or liquid extractable substances, CO2 expansion and salting-out assisted liquid-liquid extraction (CO2 SALLE), and optimized extraction process energies.